We unveiled our proprietary robotic delivery system that is at the core of our radical new tunnelling method, at the recent British Tunnelling Society (BTS) Conference and Exhibition.

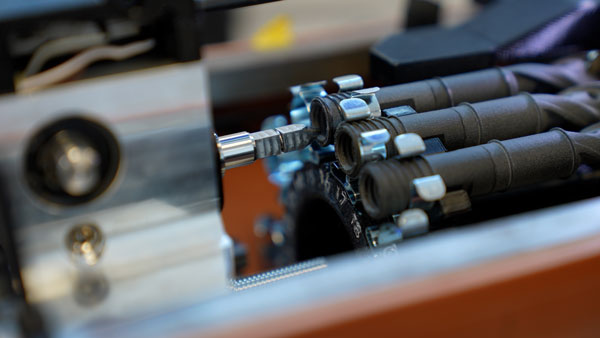

hyperTunnel engineers demonstrated how swarms of its hyperBot robots can transport cartridges of construction chemicals through horizontal directional drilling (HDD) bore pipes to 3D-print a tunnel in the ground using completely new construction techniques. This scalable and modular approach will make tunnel building, repair, enlargement and monitoring, faster, cheaper, safer, more environmentally-friendly and involve much less project risk than current tunnelling methods.

The concept, which is currently under advanced testing at various sites in the UK, is supported by a suite of integrated technology approaches. These include digital twins and digital underground surveying, supported by AI and VR, the majority of which have been proven in other sectors.

“We have been overwhelmed by the interest and support in the hyperTunnel approach from within the tunnelling and underground construction industry, and I genuinely hope we have convinced new friends to join a long overdue new movement within tunnelling, globally,” commented co-founder and co-CEO of hyperTunnel, Steve Jordan.

hyperTunnel’s chairman, Mark Carne, formerly chief executive of Network Rail, presented significant details of the new methodology as part of the two-day conference programme.

“The advantages of hyperTunnel’s form of underground construction are clear to see: nobody goes underground until the tunnel is built, so it is far safer, and because the process is much faster than traditional methods, there is much lower cost. Asset owners will surely be attracted to the long term ability hyperTunnel provides, to be able to precisely monitor the behaviour of the whole tunnel over time,” said Mark Carne.

The hyperTunnel method at-a-glance

Whereas the conventional method is to dig a hole then build the tunnel, hyperTunnel first builds the tunnel, then digs the hole.

A significant break from convention is that the hyperTunnel method does not create the hole by pushing through the ground with a boring machine or drill and blast. Instead, it 3D-prints the tunnel inside the ground, working to a digital twin created using completely new levels of data generated by hyperTunnel’s digital ground surveying techniques.

Using horizontal directional drilling (HDD) a series of bore pipes are drilled in the geology to form the outline of the tunnel. With precision accuracy, a number of semi-autonomous robots move throughout the inside of the bores to create the structural shell of the tunnel using swarming techniques. After the geology within the shell is disrupted, spoil is removed with a remote-controlled excavation shield. A continuous concrete layer can then be sprayed onto the shell and the construction completed, if required, with custom linings. Secondary bore pipes are used to house monitoring technologies which improve long-term tunnel maintenance and safety.